Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

You should know the main parts of a combine harvester. These are the header, reel, cutter bar, auger, conveyor, threshing drum, concaves, separation system, cleaning mechanism, grain tank, and unloading auger. Each part helps the combine work well and gives better harvests. If you learn about these parts, you can find problems early. This helps you stop breakdowns and makes your harvester last longer.

Component Type | Impact on Harvest Quality | Impact on Machine Lifespan |

|---|---|---|

Yield Monitoring | Better crop results | Less damage from smart choices |

Automated Controls | More exact harvesting | Less stress on the machine |

Advanced Threshing | Fewer lost grains and less harm | Harvester lasts longer and works better |

Learn the main parts of a combine harvester. Knowing parts like the header, reel, and threshing drum helps you spot problems early.

Regular care is very important. Check and clean parts like the auger and cleaning system after each use. This stops breakdowns and helps the machine last longer.

Change settings for best results. Set the drum speed and concave clearance the right way. This lowers grain loss and makes the harvest better.

Keep your combine clean. Clean the grain tank and unloading auger often. This helps the machine work well and stops spoilage.

Get help from experts. Contact FMWORLD for technical support and training. This can help you get better at harvesting and taking care of your equipment.

Knowing the main parts of combine harvesters helps you do better in your fields. Each part has a job. Some cut and gather crops. Others move crops through the machine. These parts help you keep more grain. If you know how these parts work, you can find problems early. This helps your machine last longer. It also helps you get better harvests.

The header is the first part that touches the crop. It cuts and gathers the crop into the machine. Different combines use different headers. Each header fits certain crops and field types. A standard header works for many crops. A flex platform header bends to follow bumpy ground. This is good for soybeans. A draper header uses a belt to move crops fast. A corn head is made just for corn. The right header helps you harvest well and keep more grain.

Header Type | Description |

|---|---|

Standard Header | Uses a knife cutter bar and reel for cutting and gathering many crops. |

Flex Platform | Bends over uneven ground, perfect for soybeans. |

Draper Header | Moves crops fast with a belt, often used for wheat. |

Corn Head | Made for corn, strips stalks and leaves. |

Rowcrop Head | Reduces weed seed pickup when harvesting small grains. |

You can get these advanced headers in FMWORLD harvesting machines. We make each cutter head to fit your needs. This helps you get the most from every acre.

The reel and cutter bar work together at the front. The reel pushes the crop to the cutter bar. The cutter bar slices the stems. This helps crops move smoothly. If these parts do not work well, you may lose grain. You should check these parts often for damage. Sharp cutter heads mean less stress on your combine. They also help you get better harvests.

Tip: Keep your cutter bar sharp. Adjust your reel to match crop height. This easy step can stop breakdowns and help you harvest better.

After cutting, the auger and conveyor move crops inside the combine. The auger is a spiral blade in a tube. It carries crops from the header to the threshing area. The conveyor keeps crops moving steady. This helps the combine separate grain from straw. Good auger and conveyor parts help you avoid jams. They keep your combine running well.

Component | Description |

|---|---|

Auger tube | Long tube that moves grain from the header to the threshing drum. |

Auger flighting | Spiral blade that pushes grain along the tube. |

Unloading spout | Directs grain into a trailer or bin after cleaning. |

FMWORLD Agricultural Machinery gives you strong auger and conveyor systems. Our machines use tough parts to keep your work easy and fast.

When you know your combine harvester parts, you can make smart choices. This helps you stop breakdowns. It also helps you get better harvests and makes your combine last longer. If you want to learn more or need help picking the right parts, talk to our team at FMWORLD. We are always here to help you succeed.

You rely on the threshing drum to separate grain from straw and chaff inside your combine. The drum rotates and uses drum bars, concaves, and rasp bars to break the crop apart. Drum bars start the threshing action. Concaves and rasp bars help with separating the grain from the rest of the plant. This process is key for getting clean, whole grains and keeping your harvest quality high.

If you set the drum speed too high, you can lose more grain and increase breakage. The design and speed of the threshing drum affect how much grain you keep. Look at the table below to see how drum speed changes grain loss rates:

Drum Speed (r/min) | Grain Loss Rate (%) | Breakage Rate (%) | Impurity Rate (%) |

|---|---|---|---|

505/680 | 1.94 | 0.21 | 0.56 |

506/683 | 1.87 | 0.18 | 0.55 |

Tip: Use the lowest drum speed that still separates the grain well. This helps reduce grain loss and keeps your crop in better shape.

Check the drum bars and rasp bars for wear or damage.

Clean out any stuck material after each use.

Lubricate moving parts as recommended in your manual.

Adjust drum speed based on crop type and field conditions.

Concaves and rasp bars work together to separate grain from the crop. The threshing drum rotates against the fixed concave. This creates friction, which helps with separating the grain. Rasp bars, with their teeth, rub the crop and make the process more effective.

You need to adjust the concave clearance for the best results. If the clearance is too tight, you can damage the grain. If it is too wide, you may not separate all the grain. Start with a wider setting and tighten it slowly. Watch the grain sample to see if you need more changes. Proper adjustment helps you reduce grain loss and keep grain quality high.

Inspect for cracks or worn teeth on rasp bars.

Clean the concave area after each harvest.

Replace damaged parts right away.

Make small adjustments during the season to match crop conditions.

The separation system in your combine uses advanced separation mechanisms to move the threshed material. It separates the grain from straw and chaff. Clean grain goes to the grain tank, while the rest moves out of the machine.

You can reduce grain loss by checking the separation system often. Make sure all parts move freely. Adjust settings if you see too much grain in the straw. Good separating keeps your harvest efficient and your losses low.

Clean all screens and sieves after each use.

Check for blockages or worn parts.

Adjust the settings for different crops.

Schedule regular inspections to keep the system running smoothly.

Note: Regular maintenance of your combine’s threshing and separating parts helps you prevent breakdowns and extend your harvester’s life.

You want your grain to be very clean. The cleaning system in a combine has many parts. These parts take out chaff, dust, and other things you do not want. Screens, fans, sieves, and airflow all help clean the grain. Screens catch big pieces of debris. Fans blow away light chaff. Sieves shake and sort out small bits. Airflow lifts dust and light stuff away. This makes your grain better and helps stop spoilage.

Mechanism | Description |

|---|---|

Screens | Separate clean grain from chaff and debris. |

Fans | Blow away lighter materials to enhance grain purity. |

Sieves | Shake to isolate grains from impurities. |

Airflow | Removes lighter materials, improving overall purity. |

Tip: Clean the screens and sieves after every use. This keeps your combine working well and stops blockages.

If you take care of the cleaning system, your combine works better. You should check these places often:

Area to Clean | Importance |

|---|---|

The grain tank | Prevents grain buildup and maximizes capacity. |

The cleaning system | Prevents debris buildup and ensures efficient operation. |

The engine compartment | Prevents debris buildup and ensures efficient engine operation. |

The radiator | Prevents debris buildup and avoids engine overheating. |

The grain tank holds your clean grain until you unload it. Newer combines have tanks that hold 3,000 to 14,100 liters. Some, like the Yanmar AW82V, have a small tank of 490 liters. A bigger tank lets you harvest longer before you unload. Always keep the tank clean. This stops grain from building up and keeps your combine running well.

The unloading auger moves grain from the tank to your trailer or truck. It must work fast and smooth. Some augers can unload up to 186 liters each second. You can get augers in different lengths, like 7.9, 8.7, or 9.45 meters, to fit your needs.

Feature | Specification |

|---|---|

Peak unloading rate | 186 L/s (5.3 bu/sec) |

Unloading auger length | 7.9, 8.7, or 9.45 m |

Take care of the unloading auger to stop breakdowns.

Good care makes your equipment last longer and keeps your harvest on time.

Note: If you care for your cleaning system, grain tank, and unloading auger, your combine will work better and last longer.

The chassis holds up the whole combine. It links all the main parts together. These parts are the header, feeding section, threshing unit, and cleaning section. The chassis is made from strong materials. This helps it carry heavy loads and handle bumpy fields. Some new combines have a four-point adjustable lifting crawler chassis. You can change the height and tilt. This helps you work better on uneven ground. It lets you use the combine in many fields without much trouble.

Key structural elements that boost durability:

The chassis frame holds up the machine.

Modules join the header, feeding, threshing, and cleaning parts.

Strong materials help stop damage and wear.

Modern innovations in combine harvester technology include:

Adjustable crawler chassis for better use in fields.

Height and tilt changes for safer work.

Designs that last longer in hard conditions.

Tip: Check the chassis for cracks or loose bolts before you harvest. Clean off mud and dirt to stop damage.

The engine gives power to every part of the combine. If you take care of the engine, it works well and saves fuel. Change the air and fuel filters, oil, and tune the engine often. Doing this can help you use less fuel by up to 4%. Good oil and fluids keep the engine cool and stop it from breaking. This care helps your combine last longer and work better.

Engine maintenance checklist:

Change oil and filters when needed.

Check coolant and fluid levels a lot.

Listen for odd sounds when the engine runs.

Clean the engine area to stop it from getting too hot.

Tip: Write down all engine care you do. This helps you find problems early and save money on repairs.

You use operator controls to run the combine. These controls let you start and stop the engine. You can also change harvest settings and check how the machine is working. You need to know what each control does to stay safe and work well. Before you begin, check all controls to make sure they work. Training helps you avoid mistakes and do a better job.

Essential operator control features:

Calibration helps you measure and collect crops right.

Settings let you change rotor speed, concave clearance, and fan speed.

Real-time data shows yield and moisture as you work.

Automated systems help you change speed and crop flow.

Technology/Feature | Impact on Productivity |

|---|---|

Precision farming technologies | Help you work faster and save time. |

Automated control systems | Make speed and crop flow better in different fields. |

Real-time data monitoring | Show instant yield and moisture for smart choices. |

Telematics | Let you manage the machine and farm from far away. |

Integrated yield and moisture sensors | Help you get more crops and better harvests. |

Note: Always read the operator manual and go to training. This keeps you safe and helps you use your combine the best way.

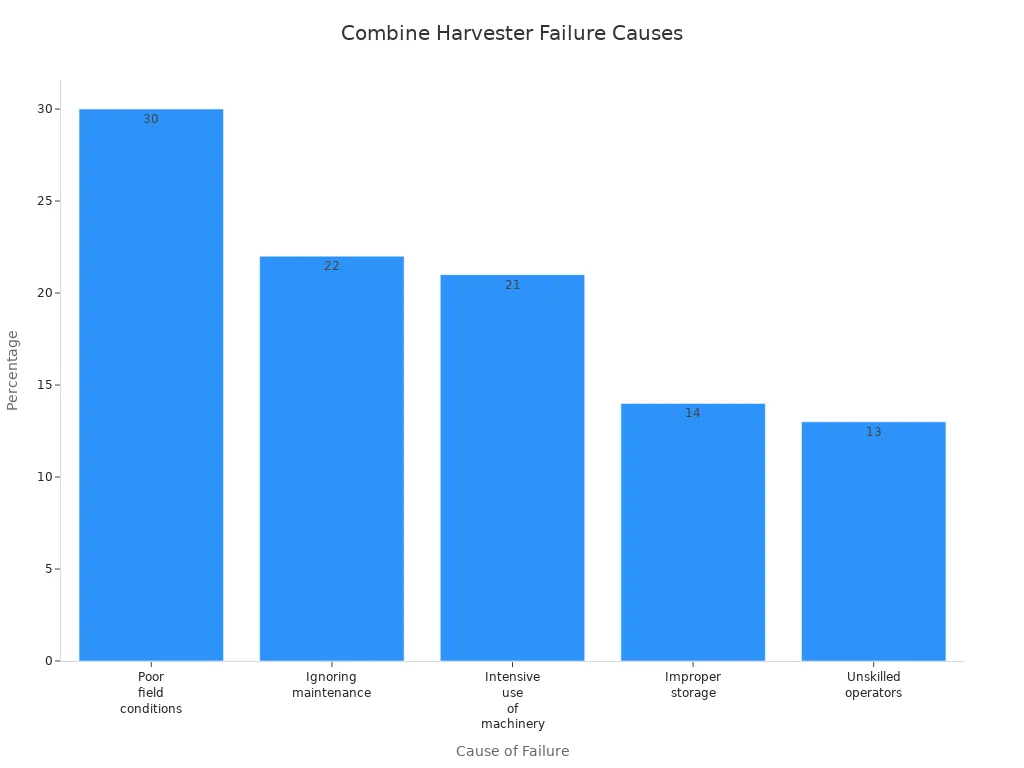

If you know what each part does, you can work better. This helps you stop big problems before they happen. The chart shows that not taking care of your combine and not knowing how to use it can cause most breakdowns.

If you check your combine often and take care of it, it will last longer. Your harvest will also be better.

Maintenance Activity | Benefit |

|---|---|

Regular inspections | Stops breakdowns and saves time |

Replacing worn parts | Makes your machine last longer and work better |

Lubrication | Helps your combine last and work well |

Keep learning about your combine. Check every part often. This will help you get better harvests and keep your machine working for many years.

You should check the header, reel, cutter bar, auger, conveyor, threshing drum, and cleaning system. These parts help your combine work well and prevent grain loss.

You should inspect and clean your combine after every use. Replace worn parts and lubricate moving parts as needed. Regular care keeps your machine running longer.

Adjust the drum speed and concave clearance. Keep the cutter bar sharp. Clean the sieves and screens. These steps help you keep more grain and improve harvest quality.

The cleaning system removes chaff, dust, and debris from your grain. Clean grain stores better and brings higher prices. You get better results with a well-maintained cleaning system.

FMWORLD provides expert technical help, hands-on training, and 24/7 support. You can access spare parts quickly. Our team helps you keep your equipment in top shape.

Email:fmworld.agro@worldgroup.com.cn

WhatsApp:+86-15906103178

Phone:+86-0511-86349102