Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

What does a rice transplanter do? Each part of the paddy transplanter helps make planting rice faster and more accurate. The rice transplanter machine moves seedlings quickly. This saves time and hard work. Knowing how these parts work helps farmers use and take care of their machines. This leads to better crops and more work done. Modern rice transplanting with machines helps farmers grow more rice, as shown below:

Metric | DSR Adopters vs Non-Adopters |

|---|---|

Yield increase | +7.69% |

Additional income | +44.3% |

Land preparation cost | 22.6% less |

Fertilizer cost | Much lower |

Irrigation cost | Much lower |

Harvest cost | Much lower |

Weed management cost | 12% higher (because of herbicide use) |

Using a rice transplanter helps save money and is better for the environment. Different types of rice transplanters, like those from FMWORLD Agricultural Machinery, help farmers in India and other places get better results in their fields. Paddy transplanter technology, along with combine harvester and tractor equipment, makes planting rice easier and more dependable.

Rice transplanters help farmers plant rice faster. They move seedlings quickly and put them in the right place. This saves time and makes work easier.Each part of the machine has a job. The seedling tray, pickup unit, conveyor, planting unit, and closing wheel all work together. They help plant rice in the right way and keep seedlings safe.Good spacing and depth help rice plants grow strong. Plants get enough sunlight and can make more rice.Modern rice transplanters have smart controls and GPS. These help plant straight rows and change for different fields.Taking care of the machine is important. Knowing how it works helps farmers stop problems. This keeps the transplanter working well and helps grow better crops.

A rice transplanter machine has many important parts. These parts help plant rice in paddy fields quickly. Each part works with the others to make planting fast and correct. Knowing how the rice transplanter and its parts work helps farmers do better and keep their machines working well.

The seedling tray is also called the seedling box. It holds young rice plants before they are planted. These trays are made from hard plastic. They are about 58 cm long, 28 cm wide, and 3 cm deep. The tray gives seedlings a safe place to grow strong. Farmers can change how many seeds go in each tray. This helps them get good seedlings and plant faster. Using 60 grams of seeds in each tray often works best. This amount gives strong seedlings and fewer empty spots when planting. The tray makes a thick layer of seedlings. This helps the paddy transplanter pick up and move seedlings without hurting them. The tray’s design helps feed seedlings evenly and keeps the rice transplanter running smoothly.

Feature/Parameter | Description/Value |

|---|---|

Tray Material | Hard plastic |

Tray Dimensions | 58 cm × 28 cm × 3 cm |

Seeding Rates Tested | 40 g, 60 g, 80 g, 100 g per tray |

Seedling Cultivation Duration | 25 days |

Key Findings | 60 g/tray balances seedling quality and transplanting efficiency |

Role of Seedling Tray | Provides a controlled environment for optimal seedling density and quality |

The pickup unit is a very important part. It uses claws or clips to grab seedlings from the seedling box. The pickup unit must be gentle so it does not hurt the seedlings. Some machines use comb-type or chopstick-type claws. The pickup unit works with the seedling feeding part. This makes sure each seedling is picked up at the right time. This helps get more than 95% of the seedlings out and keeps mistakes low. The pickup unit lets the paddy transplanter work fast and right. This means fewer missed seedlings and better planting.

The pickup unit grabs seedlings carefully.

It works with the seedling feeding part for smooth planting.

High pickup rates and few mistakes show this part works well.

The conveyor system moves seedlings from the seedling box to the planting part. It uses trays, push rods, and sometimes a hanging cup. Sensors and control systems help time the seedling delivery. This helps stop mistakes. The conveyor system must move seedlings fast and gently. Good conveyor systems can deliver over 97% of seedlings without problems. The conveyor system helps the rice transplanter work by itself. This makes planting faster and more dependable.

Aspect | Description | Operational Metrics / Technical Details |

|---|---|---|

System Components | Seedling tray conveyor, push rod, hanging cup mechanism | - |

Control Technology | PLC control, sensors, user interface | Error rate ~2.08%, success rate ~97.91% |

Contribution | Ensures accurate, timely, and damage-free seedling delivery | Supports automation and efficiency |

The planting unit is the most important part. It puts seedlings into the soil at the right depth and space. The planting unit uses arms and buckets to put seedlings in the mud. Tests show it can plant at about 3.25 cm deep. It keeps seedlings standing up at about 19.5 degrees. The planting unit works with the seedling feeding part. This makes sure each seedling goes in the right place. This part helps most seedlings live and grow the same way. No missed seedlings and good soil covering show the planting unit works well.

Parameter | Observed Value | Significance |

|---|---|---|

Planting depth | 3.25 cm | Supports seedling growth |

Seedling inclination | 19.5° | Keeps seedlings upright |

Missing seedlings | 0% | Ensures full coverage |

Hole coverage by soil | ~115% | Protects seedlings |

The closing wheel comes after the planting unit. It presses the soil around the new seedlings. This helps the roots touch the soil and get water. The closing wheel also covers the hole to keep the seedling from drying out. The angle and width of the closing wheel matter. They help seedlings stand up and cover the roots with soil. A good closing wheel helps more seedlings live and grow well.

Note: The main parts of a rice transplanter, like the seedling box, pickup unit, conveyor system, planting unit, and closing wheel, all work together. They help make planting easier and better. Each part is important for the rice transplanter to work well. This helps farmers plant faster and get more rice.

Farmers can buy new rice transplanter models and other machines, like combine harvesters and tractors, from FMWORLD Agricultural Machinery. These machines use new technology to help farmers grow rice in a better way.

A rice transplanter needs a strong transport system. This helps it move and plant rice seedlings in muddy fields. The transport system has the engine, wheels, and steering. Each part helps the machine work well and fast.

The engine is the main part of the rice transplanter. Most machines use a diesel engine or get power from a tractor’s PTO. The engine gives power to the transmission parts. These parts have shafts and sprockets. They help move the wheels and planting units. There are three main shafts in the system. These are the intermediate reduction unit shaft, the transplanting unit shaft, and the wheel axle unit shaft. Chains and sprockets connect these shafts. Their speeds match the machine’s moving speed. This helps the rice transplanter move at a steady pace. It usually goes between 0.5 km/h and 1 km/h. Engineers use computer tests to check if the system is strong enough. They make sure it can handle planting and moving. FMWORLD Agricultural Machinery uses these designs. This helps their rice transplanters work well in the field.

Wheels are very important for moving in muddy fields. Designers use special wheels or tracks to stop sinking. Some wheels look like animal feet, such as ostrich or wading birds. This gives better grip and keeps the machine from getting stuck. Other wheels have bumps or grooves. These stop mud from sticking to the wheels. These features help the machine move easily in soft, wet soil. Good traction lets the rice transplanter plant fast and evenly. FMWORLD uses these ideas in their combine harvester and tractor products. This helps farmers work in many types of fields.

The steering system helps the operator guide the rice transplanter. It lets the machine go straight and turn corners. Modern machines use GPS and smart controllers for steering. These systems keep the machine on the right path. They work even if the ground is slippery or bumpy. Tests show the best steering systems stay within 7.5 cm of a straight line. They also turn corners with only small mistakes. Some machines use fuzzy logic or model predictive control. These help the steering adjust quickly and avoid sharp turns. This makes the rice transplanter easy to use. It helps plant rice in neat rows. FMWORLD Agricultural Machinery puts advanced steering systems in their rice transplanters. This helps farmers get the best results.

Tip: A good transport system helps the rice transplanter work in tough fields. Good design means less time fixing problems and better planting.

The rice transplanter starts by gently handling seedlings. The seedling box keeps young rice plants safe and neat. The tray is sloped, so seedlings slide toward the pickup fork. A tray shifter helps move the seedlings forward. This keeps the seedling flow steady and smooth. The paddy transplanter uses a pickup unit to grab seedlings from the box. It then puts them into the mud. Operators can change the space between rows and how many seedlings go in each hill. The machine can plant many lines at once. This makes planting faster and needs less work. The process helps plant rice evenly and lets farmers finish quickly.

The paddy transplanter uses a pickup fork to get seedlings from the box.

The tray shifter pushes seedlings forward for easy pickup.

Operators set how far apart and how deep to plant.

The machine plants many lines at once to save time.

Using the machine means less hard work and fewer health problems.

Even planting helps crops grow better and more evenly.

The machine finishes transplanting fast, even with tight deadlines.

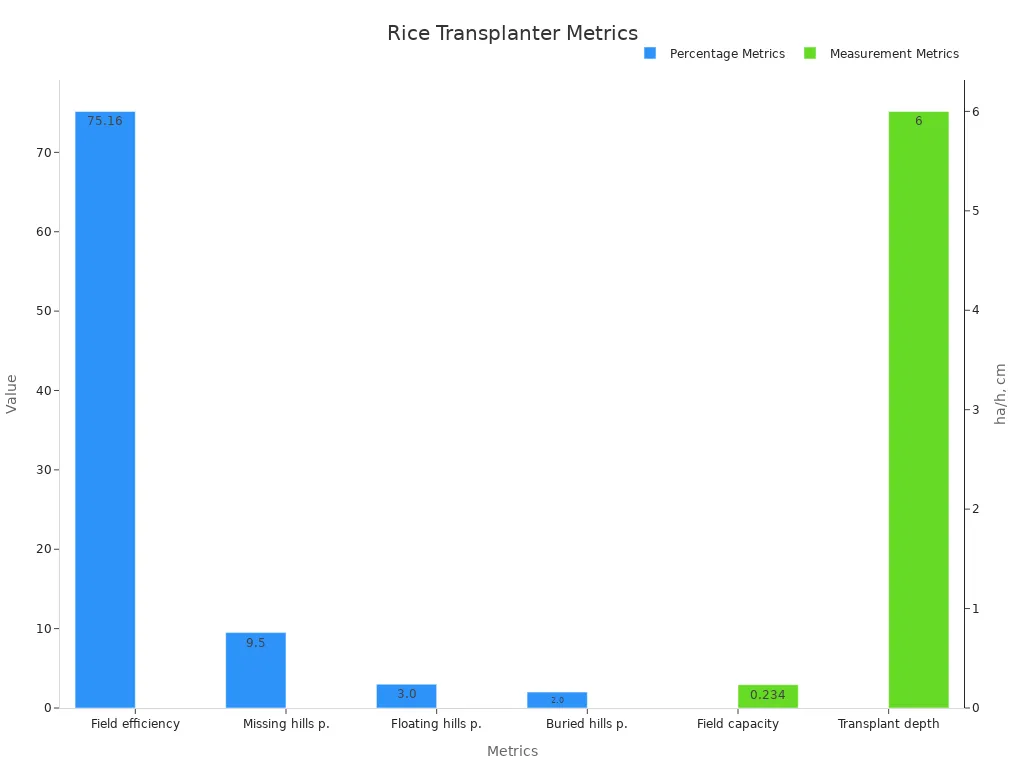

The planting mechanism puts each seedling at the right depth and space. The machine uses arms and buckets to place seedlings in the soil. This system makes sure seedlings stand up straight and get enough soil on top. The table below shows how well the planting mechanism works:

Metric | Value | Description/Condition |

|---|---|---|

Field capacity | 0.234 ha/h | Area covered per hour by the transplanter |

Field efficiency | 75.16% | Operational efficiency in the field |

Missing hills percentage | 9.5% | Percentage of hills where seedlings were missed |

Floating hills percentage | 3.0% | Percentage of hills with floating seedlings |

Buried hills percentage | 2.0% | Percentage of hills where seedlings were buried |

Transplanting depth | 6 cm | Depth at which seedlings were planted |

Standing water depth | 2.5-3 cm | Water depth during operation |

Seedlings per hill | 2-3 | Number of seedlings planted per hill |

The paddy transplanter works well and puts seedlings in the right place. This helps farmers get good results with less work.

Getting the right depth and spacing is important for healthy rice. The rice transplanter lets operators set row and hill spacing, like 15 cm × 30 cm or 20 cm × 25 cm. These settings help rice plants grow better and give more yield. Studies show that planting close together helps panicles grow strong and stops plants from falling over. Some row patterns can give up to 9% more yield. Planting close also helps the leaves get more sun and make more food.

Setting row and hill spacing helps plants get more light and food.

Good spacing helps plants use nitrogen and fill grains better.

Too many tillers can crowd the plants and lower the yield.

Changing spacing and depth helps plant rice evenly and keeps crops healthy.

When the transplanting process uses the right settings, it gives even planting and more rice. FMWORLD Agricultural Machinery makes rice transplanters, combine harvesters, and tractors to help farmers do this. Their machines help pick up seedlings, move them, and plant them just right in every field.

A rice transplanter has many parts that work as a team. The seedling tray, pickup unit, conveyor, planting unit, and closing wheel all have their own jobs. These parts work in a certain order. The seedling tray keeps the young plants safe. The pickup unit takes each seedling from the tray. The conveyor brings the seedlings to the planting unit. The planting unit puts the seedlings into the soil. The closing wheel covers the roots with mud. Working together, these parts help the machine plant fast and correctly.

Modern rice transplanters, like those from FMWORLD Agricultural Machinery, use smart navigation and GPS. These tools help the machine make straight rows and even spaces. IoT and data analytics let farmers watch the field in real time. This technology makes planting better and faster. Engineers use computer models to see how the machine, seedlings, and soil work together. These models help improve how each part works with the others. Farmers get better crops because the machine can work in many field types.

Tip: When all the parts work together, farmers get even crops and save time.

The operator interface lets the user control the rice transplanter. Simple controls help the operator set row spacing, planting depth, and speed. New machines have touch screens and smart controllers. These tools make it easy to change settings for different fields. Studies show that good operator interfaces keep planting steady, even if the machine moves at different speeds or on rough ground.

A good interface helps plant more accurately. It also lowers mistakes and keeps the machine working well. FMWORLD Agricultural Machinery puts these features in their rice transplanter, combine harvester, and tractor products. Operators can quickly change settings for new field conditions. This means the machine can plant rice well in many soils and weather.

Note: Easy controls help operators get the best results from their rice transplanter in any field.

Knowing how each rice transplanter part works helps farmers do better. It makes planting faster, gives more rice, and saves money on work. Using a rice transplanter means planting is more exact and crops grow better. FMWORLD Agricultural Machinery sells strong rice transplanters, combine harvesters, and tractors to help with this.

Cleaning the machine, checking it often, and using it right stops most problems and helps it last longer.

Looking at parts, changing them when needed, and storing the machine right keeps it working well and stops delays.

A new study from China says that learning about the machine helps fix problems, grow more rice, and spend less. Farmers who use this knowledge get the most from their machines and keep them working for many years.

A rice transplanter helps plant rice seedlings in fields. The machine puts each seedling at the right depth and space. This saves farmers time and helps them grow more rice.

The seedling tray keeps young rice plants safe. The pickup unit gently takes each seedling from the tray. They work together to move seedlings smoothly and correctly for planting.

Correct spacing lets rice plants get enough sun and food. This helps each plant grow strong and healthy. Good spacing also stops plants from fighting for space and helps get more rice.

Yes. FMWORLD rice transplanters can be used with harvesters and tractors. Farmers use these machines together to get fields ready, plant, and harvest rice.

Farmers can go to the FMWORLD Agricultural Machinery product page for more details. The website has information about rice transplanters, harvesters, and tractors. It also gives product details and support.